Radiometric non-contact measurement

Radiometric and Microwave measurement are solutions for difficult conditions where conventional measuring is inapplicable because of high temperature, pressures, or abrasive materials.

It is non-intrusive with no contact on the material to be measured. Specific measurement applications are: Level, Density, and Bulk weight in conveyors, bunkers, silos, and pipe systems. Further applications are moisture measurement in conveyors, pipelines, and oil separators.

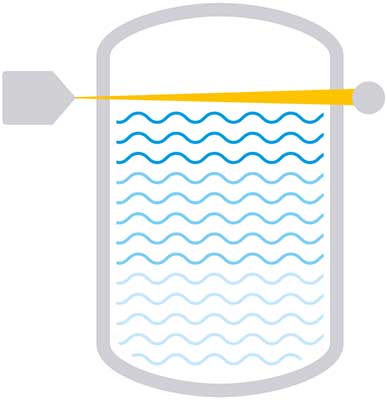

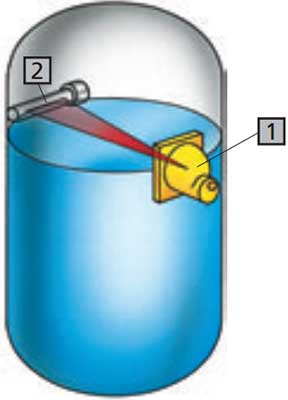

Level Switch measurement system is applicable where one or more alarm levels of liquids or bulk solids have to be monitored. Level switch is suitable for installation on all types of vessels or bunkers like storage tanks, hot-storage bunkers,

vessels with agitators, high-pressure reactors, cyclones or feeder chutes.

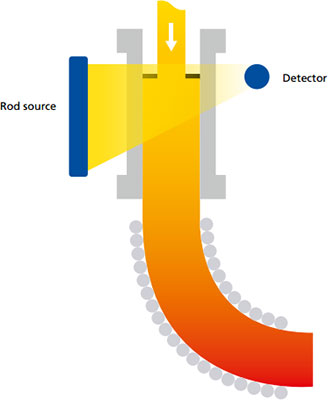

Arrangement of a level alarm switch is shown in picture. The shielded radiation source is installed outside the vessel at the height at which the

alarm must be indicated. The radiation detector is mounted at the same height on the opposite side of the vessel. Detector signal is transmitted to the evaluation unit.

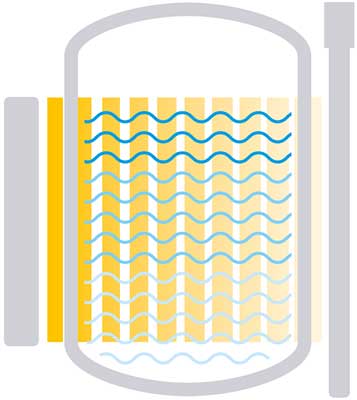

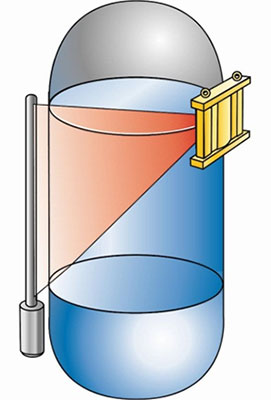

Continuous Level Measurement ranges from a few millimeters up to several meters to cover the entire span of the vessel. Applications are mainly located at extreme process environments since radiometric measurements are not affected by temperature, high pressures, or dusty environments. Strong foaming or corrosive or abrasive media are no problem for our level measurement system. Possible applications are:

- (hot) storage tanks

- vessels with agitators

- cyclones

- high-pressure reactors

- autoclaves

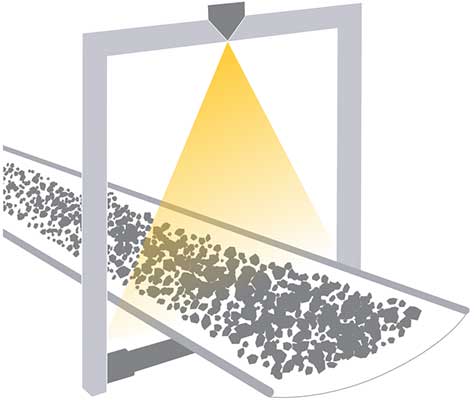

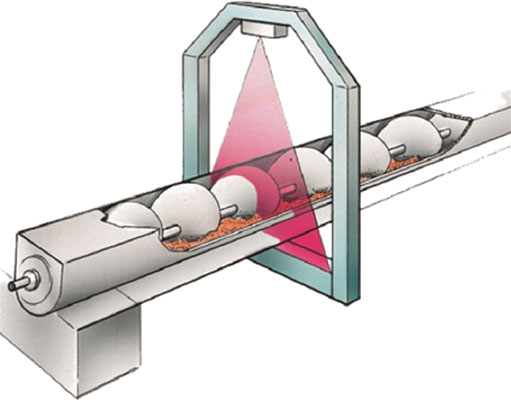

Bulk Flow Measurement is a non-contacting weighing system used in industries such as mining, building materials, power generation, pulp and paper. Suitable for monitoring of loading, dosing, mixing, and production output control. We measure Current flow rate, Total solid mass (Tonnage), Batch processes. Measurement can be performed on all conveyor systems such as:

- Screw conveyors

- Drag chain conveyors

- Conveyor belts

- Bucket elevators

- Pipeline

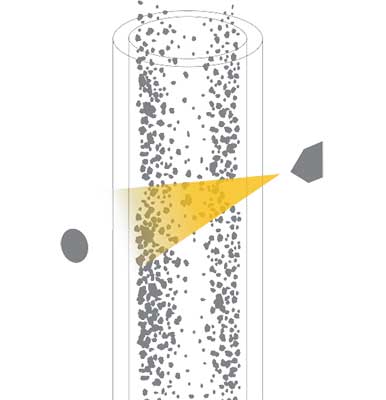

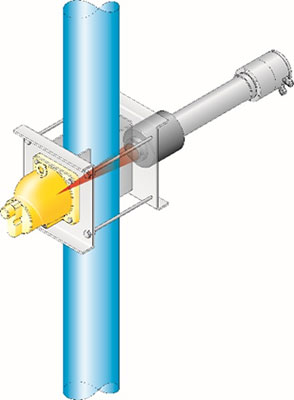

Mass flow measurement

- Non-contacting mass flow measurement as a simple clamp-on solution.

- No installations in the pipe, no disturbance of the material flow.

- For all kinds of liquids, ideal for suspensions and slurries.

- Usually, the offsetting with the speed signal takes place in the transmitter.

- At customer‘s request, the solids concentration can be indicated on its own and the calculation of mass flow takes place in the control room.

Mould Level Measurement in continuous casting is critical for production of high-quality steel and prevention of steel overflows and breakouts. Different arrangements can be used for steel level measurement. Besides the typical installation on slab and billet casters, it is also successfully applied on beam-blank and round casters.

- Can be used for all mold formats

- Fully compatible with electromagnetic stirrers and brakes

- Extremely short cycle time of 5 ms

- Continuous mold powder measurement

- Mould powder measurement cycle of 0.5 s

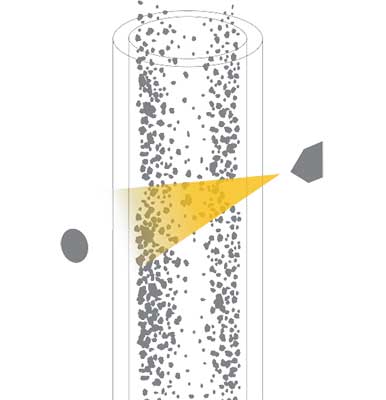

Density Measurement is used for continuous process monitoring on pipelines and in vessels. Density, concentration and solids content can be determined without contact and without affecting the flow properties of the measured material. Measurement can be performed on liquids and mixtures of any type, including acids, alkalis, solutions, emulsions and suspensions. It is also possible to determine the bulk density of solids, such as granulates or powders.

Selected References: