Microwave Measurement

For moisture or water content, liquid concentration, pulp, paper, wood chips, and sugar brix.

Microwave Measurement for moisture content, dry substance, or concentration in varied products during ongoing production, either on conveyor belts, chutes, pipes, or vessels. Our microwave systems can be used across a wide range of industries such as the food industry, power plants, mining, and paper mills.

Micropolar offers measuring capabilities for:

- Bulk materials

- Liquids

- Powders

- Suspensions

- Pastes

- granulates

Monitor the water content of products such as dairy, milk of lime, silica, tar, water in oil/oil in water, sewage and measure moisture content of bulk materials at a conveyor belt, bunker or silo, and chute.

Examples of the successful use of MicroPolar:

- wood chips

- wood fibres

- sand

- carbon in fly ash

- lignite and coal

- sand-lime brick

- fertilizer

- hay and straw

- coking coal

- bauxite

- phosphate

- tobacco

- calcium carbonate

- starch pellets

- gypsum

- clay mass

- cereals

- chip board shavings

- sugar beet chips

- potato cuttings

- granulated slag

- foundry sand

- bentonite

Microwave Measurement for Sugar Industry. Our systems are in operation in sugar mills all over the world. They are applied in multiple process steps in the course of the sugar manufacturing process. Our instruments show outstanding accuracy for °Brix value, concentration, density or the moisture content, and do not require regular maintenance.

- °Brix measurement of raw, thin and thick juices, in crystallizer, seed magma, mixers, in solution and molasses.

- Solid matter content measurement on raw and industrial milk of lime.

- Moisture content of crystallized sugar during sugar cube production as well as of pressed pulp, dry pulp or bagasse.

- Reliable and continuous online concentration measurement.

- Maintenance-free system, No wear and tear of components.

Measuring °Brix in the Evaporation – After each stage of evaporation the °Brix content of the sugar juice is measured. Our microwave system provides real-time information on the sugar content and allow for reliable control of the evaporators.

- °Brix concentration of different juices at the inlet, recirculation, or outlet of evaporator.

- Microwave system MicroPolar LB 565 with FlowCell or container probe.

Measuring °Brix in The Crystallizer – Juice concentration (°Brix) is monitored throughout the crystallization process and a precise determination of the seeding point can be determined. The systems are applied in all crystallization stages.

- °Brix concentration of sugar juice and massecuite

- Discontinuous and continuous crystallizers – vertical and horizontal; e.g. in each compartment, massecuite outlet

- Microwave System MicroPolar LB 565

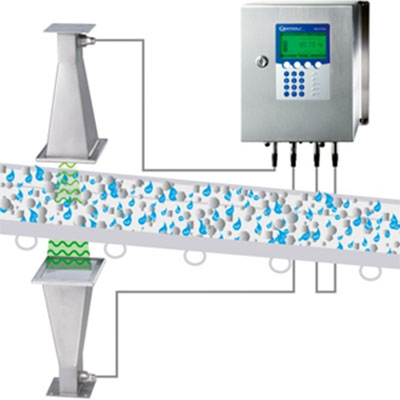

Bagasse Moisture Measurement – Bagasse byproduct of sugar cane are further processed to be used as fuel for power generation. Both bagasse and beet pulp contain water, which needs to be measured in order to ensure continuity and high quality of the downstream processes.

- Dry substance / moisture of bagasse, sugar beet pulp, beet slices or pellets

- Measurement on a conveyor or chute prior to drying and processing

- Microwave system MicroPolar LB 567 with horn antenna

Measuring Density of Milk of Lime – After extracting raw juice from sugar beets, the juice passes through carbonation wherein milk of lime and carbonation gas are is added as a reactant. The quality of the milk of lime has to be monitored in several stages to achieve better purification.

- Density of milk of lime (e.g. in °Bé)

- Several stages throughout purification in the classifier, pipelines or tanks

- MicroPolar LB 565 with FlowCell or container probe

Selected References:

Sugar brix measurement using microwave technology at sugar mill in Negros Philippines

Microwave brix measurement pipe installation at sugar mill in Negros Philippines