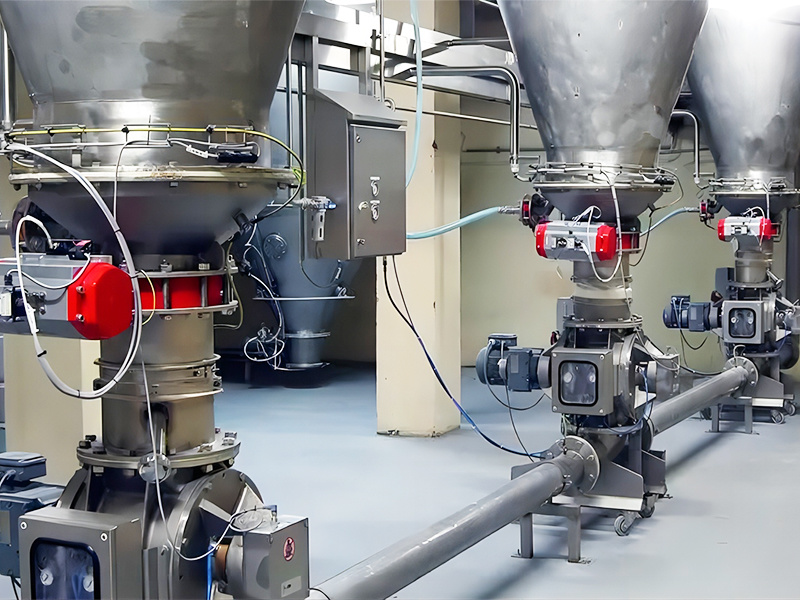

Pneumatic Conveying System

Pneumatic conveying for transporting powder, granular solid, or other raw materials using air flow with a closed system, minimizes dust and mixing of other impurities in the material, while promoting a clean workspace. Reduce packing, handling, transportation time, and cost. *For unstable chemical raw materials, inert gas conveying can be adopted.

Our pneumatic conveying pipeline can be flexibly arranged depending on the factory’s existing equipment configuration.

Dilute Phase

Positive pressure dilute phase conveying – For single point to point material conveying, using Roots blower. Suitable for less abrasive materials that can withstand high velocity without degradation.

Dense Phase

Positive pressure dense phase conveying – For fragile, abrasive, or heavy material. High pressure, low velocity using air compressor.

Negative Pressure Conveying

Negative pressure conveying – Vacuum conveying uses Roots pump with pressure that is lower than ambient pressure and eliminates risk of material leakage. Suitable for materials with combustible dust.

Air Flow Mixing

Air flow Mixing – High capacity, sealed automated mixing for granule and powder.

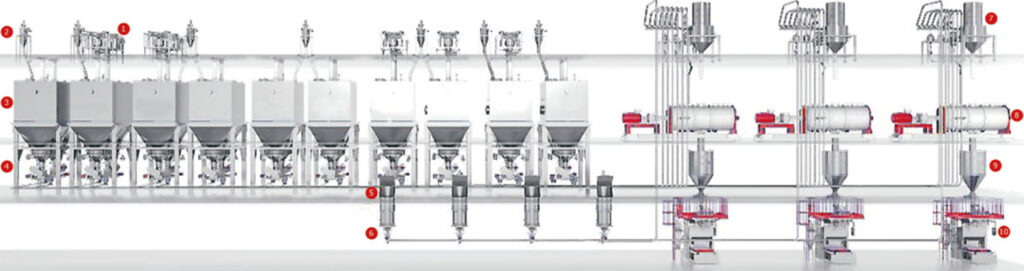

Chemical Raw Material Conveying

For petrochemical, fine chemicals, resin, ceramic powder, and inorganic material

1 Ton bag unpacking

2 Dust collector

3 Storage

4 Activation hopper

5 Pouch unpacking

6 Screw feeder

7 Suction weighing

8 Blender

9 Temporary storage

10 Packing machine

Plastics Industry Conveying

For PVC (Polyvinyl Chloride), PP (Polypropylene), PC (Polycarbonate), PEI (Polyetherimide), PA (Nylon), PE (Polyethylene), PA (Polyamide), POM (Polyoxymethylene)

Other applications include

PET bottle recycling

Degradable Plastics

Food and Beverage Conveying

For powders, particles, liquid, paste, milk powder, bran, yeast, millet

1 Tank Feeding

2 Manual Feeding Station

3 Dehumidifier

4 Roots Blower

5 Intake Storage Silo

6 Sifter

7 Temporary Storage Silo

8 Automated Weighing

9 Mixer