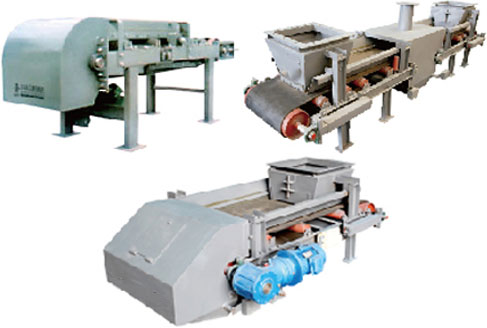

Coal feeder, belt feeder, and belt scale

Coal feeder

For coal-fired powerplant and bed boiler in thermal powerplants. High precision feeding, dynamic metering, to effectively match boiler operation process. Automatically control hot air backpressure for safer and reliable operation.

- Coal enters control gate and passes through weighing area of electronic belt scale with weight sensor.

- Weighing bridge converts the coal weight into voltage signal and sends it to integrator.

- Integrator receives pulse signal from photoelectric speed sensor installed on the tail drum and obtains cumulative amount by weight and speed signal.

- Temperature sensor installed inside the feeder compares with set value, when the critical point is reached, the switch signal is output to the control system to quickly close the high-temperature isolation gate of the coal outlet, preventing hot air from flowing back.

| W (mm) | 500 | 650 | 800 | 1000 | 1200 |

| H (mm) | 1400 | 1500 | 1700 | 1800 | 2000 |

| D (mm) | 800 | 950 | 1100 | 1300 | 1500 |

| Capacity Tons/Hr | 0-25 | 25-40 | 40-60 | 60-100 | 100-120 |

| Accuracy | ±0.5% | ||||

| Speed | frequency conversion | ||||

| Current output | 0 ~ 20mA or 4 ~ 20mA | ||||

| Interface | RS232 or RS485 | ||||

| Temperature | ≤80° C | ||||

| Pressure tolerance | ≤0.35MPa | ||||

Weighing rubber belt feeder

Weighing sensor with double-layer sealing. The Speed signal uses photoelectric encoder.

Optional open-loop or closed-loop control. Alarm with material blocking, material breaking, belt deviation.

- Conveying capacity: 0.5 to 1000t/h

- Belt width: 500 to 1400mm

- Inlet and outlet center distance: ≥1200mm

- Material size: ≤100mm

- Measuring accuracy: +0.5%

- Speed regulation: frequency conversion

- Interface: RS232 or RS485

- Current output: 0 ~ 20mA or 4 ~ 20mA

Coal bunker blockage clearing

Blockage removal in coal bunker through rotating force to break up materials.

The unit construction consists of a blockage clearing machine with disk and reducer.

The disk is installed on the output shaft, controlled by the reducer to drive the disk rotation at high speed.

Sensors monitors the the coal bunker and detects blockage in real time.

Selected References: